The Biggest Supply Chain Challenge that Mid-Size Manufacturers Face Today And How to Tackle It

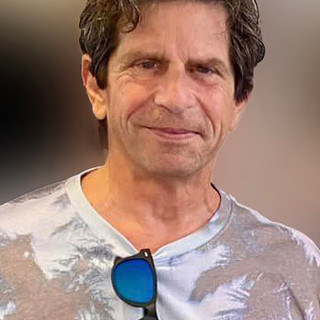

- Bennet Gold

- Oct 13, 2025

- 4 min read

Over my many years working with mid-size as well as global manufacturers I’ve learned that your supply chain can make or break your business. And while every year brings its own set of challenges, right now one issue is standing out above the rest and that’s forecasting and demand planning in an unpredictable market.

Whether you’re producing industrial components, packaging, food products, or specialty goods, the same theme keeps surfacing in my conversations with executives: “We just can’t get the forecast right.”

And it’s no surprise why. Between shifting customer demand, fluctuating input costs, global instability, and labor shortages, predicting what’s coming down the line feels a lot like reading tea leaves, yet at the same time, reliable forecasting is the bedrock of efficient operations. If your forecast is off, everything else downstream suffers. Your inventory piles up, working capital gets tied up, customers are disappointed, and profitability takes a hit.

So, what can mid-size manufacturers do about it? The answer isn’t to aim for “perfect” forecasting because that doesn’t exist. Instead, it’s about building agility into your planning process and creating systems that help you respond faster when things inevitably shift.

Here are some of the strategies I help my clients implement:

1. Break Down Silos Between Sales, Operations, and Finance

One of the biggest reasons forecasts fail is that each department is working from its own set of numbers. Sales is optimistic, operations is conservative, and finance just wants a clean spreadsheet. The result is mismatched assumptions and a plan that doesn’t reflect reality.

A more effective approach is a true S&OP (Sales and Operations Planning) process that brings all stakeholders together on a regular basis to align on demand assumptions, review market intelligence, and make joint decisions. This doesn’t just improve forecast accuracy; it also builds trust across the organization and ensures everyone is rowing in the same direction.

2. Invest in Better Data (and Use It Wisely)

Most mid-size manufacturers are sitting on more data than they realize, such as customer orders, production runs, supplier lead times, and market signals. But too often, that data is scattered across different systems or isn’t being analyzed effectively.

You don’t need to jump straight into expensive AI platforms, but even simple steps like integrating ERP data with sales history, or using visualization tools to spot trends, can be game changers. The goal isn’t just “more data”, it’s better insights.

Technology is only as good as the people using it. Training your team to interpret and act on data is just as important as the software you select. Training must never be overlooked.

3. Rethink Inventory Strategy

Inventory used to be seen as a safety net where you keep extra stock “just in case.” But in today’s market, holding excess inventory can be just as damaging as not having enough.

A smarter approach is segmenting your inventory:

A-items (critical, high-demand products) may justify a buffer.

B- and C-items can often be shifted to a leaner, make-to-order approach.

This requires a more nuanced understanding of your product mix, customer expectations, and supplier reliability. It’s not about cutting across the board, it’s about aligning inventory strategy with business priorities.

4. Build Stronger Supplier Partnerships

Another driver of forecast headaches is supplier inconsistency. If you can’t count on suppliers to deliver on time, even the best forecast won’t help.

Mid-size manufacturers don’t always have the leverage of large enterprises, but they do have the ability to build stronger relationships. That means open communication, sharing forecasts with suppliers, and developing joint contingency plans. In many cases, suppliers are willing to prioritize customers who treat them like partners rather than transactions. Frankly, it’s the way I like to work, too.

5. Embrace Scenario Planning

Instead of locking into one forecast, I encourage clients to work with multiple scenarios. For example:

Best case (high demand)

Expected case (steady demand)

Worst case (slowdown)

This way when the market shifts, and it will, you’re not scrambling from scratch. You’ve already thought through the implications and know what levers you can pull, whether that’s adjusting labor schedules, shifting production lines, or renegotiating supply contracts.

Why All of This Matters Now

The stakes are higher than ever. Mid-size manufacturers are being squeezed from both sides with customers demanding faster turnaround times and higher service levels, while suppliers pass on rising costs and longer lead times. Add in the challenge of retaining skilled labor, and the margin for error is slim.

The manufacturers who will thrive aren’t the ones who can predict the future with certainty. They’re the ones who can pivot quickly, make smarter use of their data, and foster true alignment across their organizations.

When clients come to me, they often feel overwhelmed by the complexity of their supply chains. My role is to simplify it by helping them focus on the few changes that will have the biggest impact.

Right now, that means taking a hard look at forecasting and demand planning. If your forecasts feel more like guesses than strategies, you’re not alone. But you don’t have to stay stuck in reactive mode. With the right processes, data, and partnerships, you can move from firefighting to forward planning and that’s where sustainable growth begins.

Here are 5 ways I help clients get ahead:

· Break down silos between sales, ops & finance to create one aligned view.

· Invest in better data and actually use it.

· Segment inventory (not all products deserve the same strategy).

· Treat suppliers like partners, not just transactions.

· Plan for multiple scenarios so you can pivot fast.

The manufacturers who thrive aren’t the ones who “guess right.” They’re the ones who can adapt quickly and confidently.

Comments